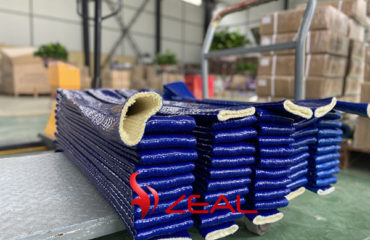

Heat-resistant sleeve, is woven from glass fiber yarn, coated with a layer of Silica Gel, can prevent the spray of molten iron, and not damaged by high temperature and flame, has good heat resistance, heat insulation, fire resistance and other properties, the utility model can effectively solve the problems arising from the high ambient temperature in the use process of the pipeline equipment.

The particularity of heat-resistant and heat-insulating casing material ensures that it has many characteristics that can not be replaced by other similar materials: High Temperature Resistance, heat insulation, flame retardant, electrical insulation, chemical stability, weather aging resistance, cold resistance, water Resistance, oil resistance, ozone resistance, voltage resistance, arc resistance, corona resistance and so on.

Excellen thig htemperatureresistance

The heat-resistant sleeve can be continuously exposed to a high temperature of 260 ° c without damage and can withstand temperatures of up to 1,090 ° C for 15 to 20 minutes and 1,650 ° C for 15 to 30 seconds, its unique flame-retardant properties in addition to the effective protection from high-heat pipeline burn injury, but also can greatly save the cost of heat energy loss.

Good thermal insulation performance

Heat-resistant and heat-insulating sleeve has better thermal stability than other polymer materials, as well as the role of radiation resistance and heat insulation, to prevent accidents and reduce energy consumption, it can also prevent the heat of the medium in the pipeline from being directly transmitted to the surrounding environment, which makes the temperature of the workshop too high and saves the cost of cooling.

Unique chemical stability

The heat-resistant and heat-insulating sleeve has strong chemical stability. The silicone has no reaction to oil, water, acid and Alkali. It can be used for a long time and does not age up to 260 °C. because the surface is coated with silicone, it is not easy to be decomposed by ultraviolet light and ozone.

Anti-splash, multiple protection

In the smelting industry, the medium temperature in the electric furnace is extremely high, easy to form high temperature spatter (welding industry is also the same) , cooling solidified in the formation of slag on the cable, the cable outer rubber hardening, and eventually brittle fracture. Then damaged unprotected equipment and cables, through multi-channel Silica Gel coating of high-temperature heat insulation, can achieve multiple safety protection, temperature resistance up to 1300 degrees C, can effectively prevent the molten iron, copper, aluminum and other high-temperature Molten Material Spray, prevent damage to surrounding cables and equipment.

Good flame retardant and fireproof performance

The cable also often burns because of local high temperature. Bai Lu du high temperature resistant heat insulation sleeve is made of high temperature resistant glass fiber braid with proper flame retardant and other special raw materials added on the surface of Silica Gel, make It have good flame retardant. Even if the fire occurs, it can prevent the spread of the fire, still can protect the integrity of the internal pipeline without damage for a long time, to the data, information and other important information rescue to provide sufficient time.

Safe and environmental protection, no pollution

Alkali-free glass fiber itself has strong tensile strength, will not wrinkle and break, vulcanization, smoke-free non-halogen non-toxic, pure oxygen non-flammable, good insulation characteristics, and then cured by Organic Silica Gel, more safety and environmental protection performance, to protect workers’ health effectively and reduce the incidence of occupational diseases. Unlike asbestos products on the human body and environmental hazards.