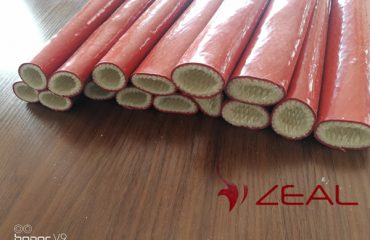

In the daily production activities of foundry industry, isolation and reduction of temperature diffusion is also a kind of daily maintenance. The high-temperature casing is a dust-proof waterproof layer with high-fluffy glass fiber as the base material and high-quality silicone rubber without surface. Its continuous working temperature is 260 ° C, and the instantaneous temperature can withstand 1650 ° C, this temperature can be applied to pipe protection in many foundry industries. High-temperature casing has good thermal insulation performance, its structure design makes the casing has double air-tightness, so it can not only fire, but also play a role in heat insulation. In the foundry industry, many equipment and pipelines can not be disassembled and installed, but high-temperature casing can be installed on-line, it can be directly coated and adjusted according to the size of the pipeline, without affecting the tightness of casing protection and structural integrity. The high-temperature casing can effectively prevent the personnel from being burned by the pipeline in the high-temperature area, can greatly reduce the cost of energy loss, avoid the direct baking of the pipeline in the high-temperature environment, and prolong the service time of the pipeline, reduce enterprise production costs!